|

|

|

#1

|

|||

|

|||

|

Auto top off: resevoir w/pump vs solenoid on RO/DI

I am installing a basement sump and can run pipe to a RO/DI unit close the sump.

What are the pros and cons of either type of topoff? The way I see it is the resevoir system needs to be manually refilled whereas the direct RO/DI does not. Dave |

|

#2

|

|||

|

|||

|

Solenoid on RO/DI is the way to go. I have used this method for over a year now and would never do anything else. Its just so darn convenient not ever having to worry about topping off.

The key word for this style of ATO is "REDUNDANCY" - Multiple float switches - Timers - redundant solenoids on input of RO unit

__________________

"You can't depend on your eyes when your imagination is out of focus." - Mark Twain |

|

#3

|

|||

|

|||

|

I agree with MeuserReef! Solenoid controlled by a timer tied to a float switch. Redundancy is KEY. Do you work in a data center Meuser?

|

|

#4

|

|||

|

|||

|

As stated - Redundancy...

I use RO/DI with a solenoid into a JBJ ATO that is plumbed into my sump through a Kent float. The ATO uses two floats (high and low) with a timer, and if that some how continues to run (doesn't time out) the float will mechanically stop the flow also. |

|

#5

|

|||

|

|||

|

I was planning on high and low float switches and a single solenoid before the RO/DI.

I may be missing something but what is the function of the timer and which timer do you use. Dave |

|

#6

|

|||

|

|||

|

The timer is built into the JBJ ATO, the solenoid will only stay energized for so long before it times out. I know that it normally takes about two min. for my sup to fill once the low switch is triggered (I have my floats very close together) so I set my timer to about four min. Even if the high switch never triggers the timer will still shut off the water flow. Then if that malfunctions the Kent float should stop the flow.

|

|

#7

|

|||

|

|||

|

This is very similar to what I will be doing but I will be using the reefwerks holding tank controller instead of the JBJ unit. Comes complete with 2 float switches and a solenoid. My timer will be on my profilux controller. My wife and I each flooded the ato container in the past and I don't want that to happen again.

__________________

Thanks, Chris |

|

#8

|

|||

|

|||

|

Quote:

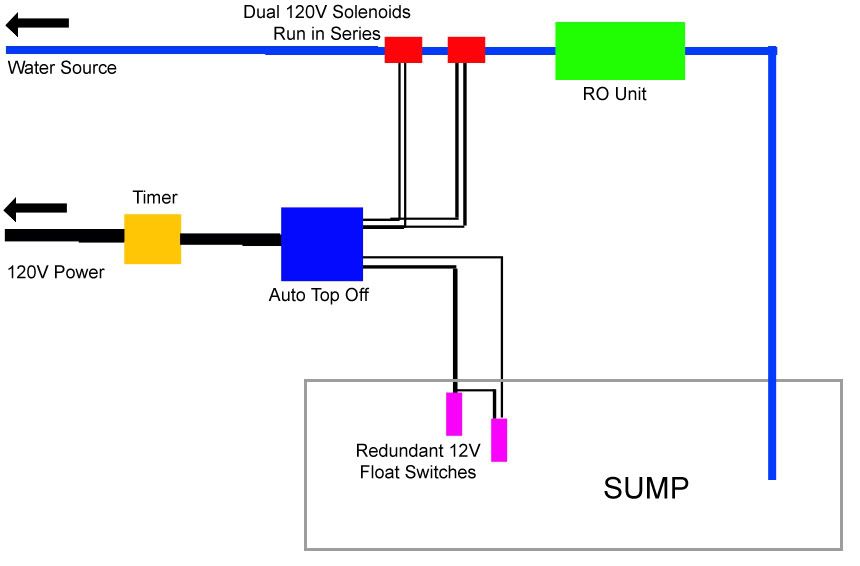

Here is a crude sketch of how my system is setup.  The timer is your protection should the float switch(es) fail.

__________________

"You can't depend on your eyes when your imagination is out of focus." - Mark Twain Last edited by MeuserReef; 12/07/2007 at 01:40 PM. |

|

#9

|

|||

|

|||

|

I simply have my RO unit tied to a automatic horse water bucket float valve I picked up at tractor supply. Using the auto-shut valve I got from Coralife to cut of the water supply when the float closes. Its been in use for two months and not a single problem and it only cost me $20 and has no metal or electronic parts, I'm happy with it.

|

|

#10

|

|||

|

|||

|

I use the float and solenoid but fill my reservoir. I then use a peristaltic pump to pull water from the reservoir and push it through a Kalk reactor on the way to the sump.

|

|

#11

|

|||

|

|||

|

Quote:

Its been working quite well for me in this configuration. I was forced to engineer around not having room for a fresh water holding reservoir, but looking back, I think I would have done this regardless (and will on future setups) **Note** I still plan on putting a Coralife manual float valve on the supply line in my sump. Since my RO has an Auto Shut-Off valve, I would be protected in the event that both solenoids became stuck in the open position.

__________________

"You can't depend on your eyes when your imagination is out of focus." - Mark Twain |

|

#12

|

|||

|

|||

|

Quote:

Float Valve |

|

#13

|

|||

|

|||

|

Thanks Saboral. The unit that I have has a rubber stopper that presses pertty tightly into the hole where the water comes out of it. I have never actually used it so it could be a piece of crap like the one you used.

In looking at the valve in the link you provided, does the valve have a cover (black part in picture) over the actual valve (red in picture)? I hope so because the metal on the balck plastic part would not be good in a saltwater environment.

__________________

"You can't depend on your eyes when your imagination is out of focus." - Mark Twain |

|

|