|

|

|

#376

|

|||

|

|||

|

Quote:

Thanks I'm gonna test mine and see what I have. I just have to get the positioning correct now. Fish are hiding from the flow like it's tornado season... lol

__________________

Let's not, and say we did! ~Paul |

|

#377

|

|||

|

|||

|

Has anyone tried running modded maxi-jets on a wavemaker? I wonder if the nylon propellers can handle the repeated slapping against the plastic stopper. I've already had one propeller rip upon startup.

|

|

#378

|

|||

|

|||

|

I found that on one of mine it would spin the housing when the propeller hits the stopper. Eventually it makes it to the notches and then the prop stops spinning.

|

|

#379

|

|||

|

|||

|

Hey everyone, after spending the entire evening and this morning going through 200+ pages I still havn't found the answer to my question. I have two maxijet mods that work great. I have two AQ's that are not moded but would like to be. I was wondering what is the best to use as a shroud and how you attach it to the powerhead. Next is the stopper issue, how was that solved it has been. Much help is needed. Thank you

__________________

Curtis http://www.curtisstolaas.com |

|

#380

|

|||

|

|||

|

anyone selling the mod kits besides mjmods? how do you cut the pvc down to fit in the mj's twist socket? i battled with a table saw and lost.

|

|

#381

|

|||

|

|||

|

You can use the existing twist lock from the MJ if you cut it out from the volute and glue it onto the PVC pipe.

|

|

#382

|

|||

|

|||

|

Quote:

D. |

|

#383

|

|||

|

|||

|

Quote:

Rusty |

|

#384

|

|||

|

|||

|

because their like 23 bucks. but i do like them, just wanted to know if there are any other sellers.

|

|

#385

|

|||

|

|||

|

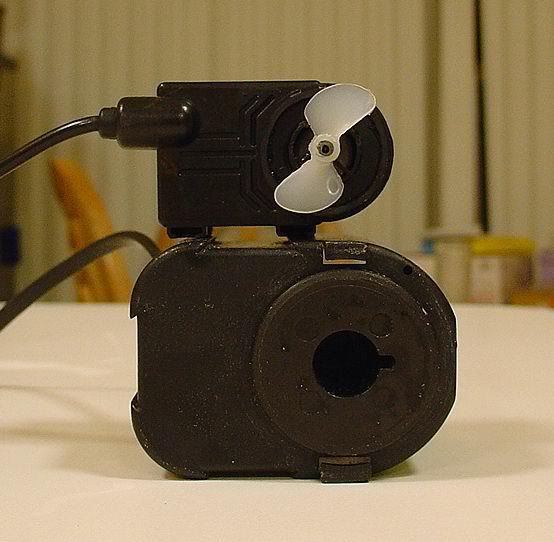

My AC 50 mod. I used a black ABS 1.5" cupling to make the housing. Some use the 2-1.5 reducer for the AC 70 but that one must be a lot bigger.

Here are some pictures, They work great and are silent. The key was keeping the prop pretty close to the top and of course as stiff as possible. I used hard airline tubing like my maxi mods but to keep everything together I used semihard water tubing from lowes instead of the soft tubing which made it go wild and wouldnt stay straight. With these extra pumps Im now pushing 43X turnover, well see how it effects everything. By the way, I do have a bare bottom so I have them pointed staight down.

__________________

Curtis http://www.curtisstolaas.com |

|

#386

|

|||

|

|||

|

how did you cut the conneting side of the shroud? did you use a dremel ?

|

|

#387

|

|||

|

|||

|

I just set the fence on the table saw at the right distance as the tabs on the pump, then only have the blade just barely above the table top and just run the pipe over the blade to the highest point then twist it so (still against the fence) to create the ring. Put an extra peace of pipe on the cupling so it is easier and safer to work with so your fingers arent near the blade. Then to make the inlets just set the fence out farther and side the pipe across. A good idea from a much earlier post is to put an elbow on the extra pipe so you just flip it over and cut the other side so the groves are pretty.

__________________

Curtis http://www.curtisstolaas.com |

|

#388

|

|||

|

|||

|

cool thanks, i thinnk i need a new blade or mybe a fine tooth one.

|

|

#389

|

|||

|

|||

|

A fine tooth one would be nice but I am using a stanard "Fire" ripping blade but it is new. My old blade wouldnt cut anything.

__________________

Curtis http://www.curtisstolaas.com |

|

#390

|

|||

|

|||

|

I have made a smallest stream pump here, check it out.

http://www.dfwmas.org/Forums/viewtopic.php?t=35152

|

|

#391

|

|||

|

|||

|

Did I read that right that the pico pump you used is 24VDC pump? Nice job BTW...

|

|

#392

|

|||

|

|||

|

Wow that is sweet, perfect for a small tank!

__________________

Curtis http://www.curtisstolaas.com |

|

#393

|

|||

|

|||

|

ooooh.

|

|

#394

|

|||

|

|||

|

Quote:

pics of it vs Maxi stream. Note that on Maxi stream, I have designed now that the rod spins along with magnet. Imo, it is quieter, the stopper is hidden and easier to make, the most difficult part is how to mount the prop onto the rod securely

|

|

#395

|

|||

|

|||

|

Very professional looking. Question - since you have the rod spinning with the magnet, is it still centered up top in the maxijet? If not, how did you keep the magnet from sticking the side of pump. Isnt that what the shaft is for, to keep the magnets apart so it can spin?

__________________

Curtis http://www.curtisstolaas.com |

|

#396

|

|||

|

|||

|

that is sweet!!!

YzGyz

__________________

YzGyz = Wise Guys ohhh and cows go MOOO!!! 2nd best way is to learn from ones own mistakes but the best way to learn is from others... thx to Randy and so many other for making reefing that much easier |

|

#397

|

|||

|

|||

|

The 3/4" carbon tubing keeps the magnet/prop centered (see pics). This is less complicate than old design, no damage to the prop and you don't have to worry about keeping the shroud perfectly centered

Last edited by quangtam7; 08/11/2007 at 03:31 PM. |

|

#398

|

|||

|

|||

|

AGIAN!!! SWEET!!!!!! imma try this one day...

YOU THE MAN!!! YzGyz

__________________

YzGyz = Wise Guys ohhh and cows go MOOO!!! 2nd best way is to learn from ones own mistakes but the best way to learn is from others... thx to Randy and so many other for making reefing that much easier |

|

#399

|

|||

|

|||

|

I see a couple potential problems here.

That spinning carbon fiber rod will drill itself right through the red/black end cap after some time. That stopper also looks a lot more complicated than say by using a small piece of rigid tubing. It also doesn't look like it would last very long either. There is a tremendous amount of starting torque from the MJ1200 and I think it will wear out the stopper before long as well. The deisgn looks cool though. |

|

#400

|

|||

|

|||

|

quangtam7 - That is great intuition! nice usage of part around the house. I guess the test of time would be all that stands in your way. How long have you been running it now?

__________________

Curtis http://www.curtisstolaas.com |

|

|