|

|

|

#1

|

|||

|

|||

|

Apply Foam Background on Running Tank?

I have followed several threads here on RC regarding using Polyurethane Pond Foam to create a textured tank background.

They are covered in coraline in no time and look like live rock. No more ugly coraline covered flat back! My tank is up and running and taking it down to foam the back is not an option I'm willing to take. It took over 8 hours to get my Aquascaping "pinned" in place using acrylic rods and would likely seriously damage/break attached corals by removing them. The following product: http://www.drsfostersmith.com/produc...Np=1&N=0&Nty=1 Is the foam I'd be interested in. If states that it dries in 10 min and cures in 1 hour. So here's the proposed plan: 1) Drain the tank to a low level where the existing aquascaping already covers the back wall 2) Dry the exposed back wall with paper towels down to the water /rock level. 3) Apply foam / shape foam 4) While waiting for the foam to cure for an hour, keep exposed corals wet by pumping/pouring water on them carefully not to splash on the curing back 5) Refill So sound off. Maybe I'm not considering something. I realize this will be a stress to my corals that I can't remove, but I believe it will be a lower stress, than if I have to dismantle the rock structure on which these corals reside. I agree that taking the tank down would provide the time and access to not only do the back right, but do the entire back. I was hoping to hear of any success failure stories of people trying similar BTW: My tank is acryllic Thanks!

__________________

What if the hokey pokey is what it's all about? |

|

#2

|

|||

|

|||

|

if it is tack free you might be able to get away with submerging it shortly after and it will cure underwater. I don't know if the curing in water would have any ill effects on livestock though. I guess you might want to run a few trials with things you don't care about killing.

|

|

#3

|

|||

|

|||

|

I think it releases chemicals as it cures, so underwater is a big no no. Why dont you sculpt the backround on eggcrate, wait till it cures, and then simply put the whole thing in the back and somehow secure it in (since ive heard that this stuff doesnt bond well to glass at all anyways.)

|

|

#4

|

|||

|

|||

|

spray it on to some egg grate that is cut to fit and after cure stick it in and prop a couple rocks on it to keep it down since it will wanna float big time!

|

|

#5

|

|||

|

|||

|

Yeah, Thanks for the responses.

My original idea was to foam something and then put it in place. The only problem is since it's an acrylic tank, the top holes are very restrictive. I did forget to mention that. It's a 100 gallon measuring 48" by 18" by 30". The widest opening (there are two) on top is 16". I am curious about whether the foam will stick well to acrylic. Since it does want to float it very well may want to peel off over time.

__________________

What if the hokey pokey is what it's all about? |

|

#6

|

|||

|

|||

|

The foam will outgas quite a bit as it cures. It will give off oils also. I would not even think about using it in a running system.

It will certainly peel of due to the buoyancy. It needs to be anchored securely in the tank. If you read many of the threads you will find that people have a hard time keeping even small structures down. Good luck! |

|

#7

|

|||

|

|||

|

Thanks Bean. Yeah there would be risk involved with applying and letting the foam cure so close to the water. I might have to figure something out there if I do it.

I like the idea of eggcrate since it provides a frame to hold the foam in place. Anyone seen people weigh down the egg crate with something? I was thinking of adding some aggregate of some sort. The average density of Rock(not live rock) is somewhere over 2 g/cm cubed. That means since water is around 1 g/cm cubed if I mix a 1 to 1 volume of rock and foam, it should cease to be buoyant. Maybe I could grind/crunch up some lace rock, or even sand and embed it in the foam as it is applied. That might require an interesting technique since the foam expands and dries quickly.

__________________

What if the hokey pokey is what it's all about? |

|

#8

|

|||

|

|||

|

I am not sure how people have kept their creations down. I just know a lot have had problems with them trying to pull away, even with a LOT of rock on them.

Yes increasing the mass of the finished product will certainly help. There was a great thread recently where a guy wove foam and real rock together, shaping the foam after it dried. It came out great. |

|

#9

|

|||

|

|||

|

My other idea would be to get my egg crate cut to the size of the back wall. Apply foam weights etc. Then run the finished product through a table saw making the 16 strips (or something close that divides 48" evenly) . Then I can actually fit through the holes in the top of the aquarium.

The result will be have several (>=3) vertical stripes where the saw went through, but I might be able to obfuscate them somewhat after they are installed and butted up to one another. I will likely have to plan my design and cuts to go through rock free sections as well, considering it's my brothers table saw and I don't think he'll appreciate me putting his new blade through rock.

__________________

What if the hokey pokey is what it's all about? |

|

#10

|

|||

|

|||

|

Have you thought about using something other than foam?

Concrete mix or ceramic? Or half and half? Cut your egg crate before you spray the foam then cut with a very sharp knife or razor at a slight angle so it hides the joint. |

|

#11

|

|||

|

|||

|

Puzzle piece you egg crate so you can Build it as 1 piece then tare it down to Install and re build in tank

I would Not want to use Ceramic or Concrete in the system at all They can wreck havoc on the PH I also wouldnt want to Build it in tank Far too risky And i tink the air flow or lack of in the tank will have an effect on it Curing in the system |

|

#12

|

|||

|

|||

|

Quote:

I agree as well about the concrete (I'm not sure about ceramic). I would have to mold it and then let it "cure" for 6 weeks in water (changing frequently). I'd like to get this done quicker than that. I like the puzzle Idea. I wont have space likely to assemble anything too complex. The previous post about cutting the egg crate first was good too.

__________________

What if the hokey pokey is what it's all about? |

|

#13

|

|||

|

|||

|

This would be permanent, but since its an acrylic tank couldn't you make the background on the egg crate and then apply weld on to secure the egg crate to the back of the tank?

__________________

The Reptile File Forum (Google It) Discussion forum dedicated to geckos, lizards, snakes, turtles, amphibians, and other reptiles. |

|

#14

|

|||

|

|||

|

Quote:

I'd still have to drain the tank to let the weldon cure. Most weld-on bonds require something like 48 hours cure time before getting wet. It's an interesting idea, but I think out of the question based on the issues I've brought up.

__________________

What if the hokey pokey is what it's all about? |

|

#15

|

|||

|

|||

|

I'm thinking my favorite solution so far is:

1) Use eggcrate as a frame. this keeps the foam together like rebar keeps cement from cracking. It will keep the foam structure intact (not fall apart) and in the shape you molded in the beginning 2) Weigh it down. Foam is not very dense. It is full of tiny air bubbles and has a strong propensity to float. The constant upward force may eventually prove destructive to the aquascaping. A reef slid may result, or at a minimum a wall will come loose taking everything on it to the surface. If the end product is more dense than water then it wont want to move from where you put it and would be a more general solution for anyone who wants to do this. 3) Apply the foam in sections. Cutting the eggcrate first and the then sculpting was a grand idea. It will allow me to sculpt the entire back as one piece. Then I just cut through the foam with a bread knife in between egg crate sections minimizing the resulting vertical stripes where the sections will meet after assembly. Assembling it in the tank will disturb the corals and fish much less than my original plan. ---------------------------- So now on to weighing it down. Anyone seen threads on previous attempts, or am I charting new territory? It seems to me every idea I come up with, I think is mine and unique, there ends up being a 25 page thread on it several years old.

__________________

What if the hokey pokey is what it's all about? |

|

#16

|

|||

|

|||

|

good idea icy1155.

|

|

#17

|

|||

|

|||

|

If it were me, I would probably get a piece of acrylic, to use as a backplate and build it outside the tank. Add some heavy rocks to the bottom, to weight it down and slide it into place once it's dry. If you have trouble holding it in place and don't mind it being permanent, a few dabs of underwater epoxy should help hold it against the back of the tank. Also I might try "curing it in a large trashcan first for a few weeks (although I think there's been some debate about the necessity of this).

__________________

Some people say, "How can you live without knowing?" I do not know what they mean. I always live without knowing. That is easy. How you get to know is what I want to know. - Richard Feynman |

|

#18

|

|||

|

|||

|

I'd also go with M's suggestion of weighting with rock near the bottom

to hold the foam down. Check this thread for ideas http://archive.reefcentral.com/forum...readid=1188352 Another thing to consider what type of lighting are you using on your tank? The foam does not hold up well to large amounts of UV you may need to coat it for protection. |

|

#19

|

|||

|

|||

|

"The foam does not hold up well to large amounts of UV you may need to coat it for protection."

That is what the coralline/other algae will do when it grows on it.

__________________

Your tastebuds can't repel flavor of that magnitude! |

|

#20

|

|||

|

|||

|

you need to realise the foam is MASSIVELY buoyant!

you need LOADS of rock to sink even the smallest bit of foam.....i had 20kg lumps of rock bobbing about like boats in my early tests! you MUST stick the egg crate to the tank if you go that way, there's no way you will hold it down by propping some rock against it. also - be careful assuming coraline will keep the UV off it - it may, but that's a LOT of coraline! (mine is epoxy coated) |

|

#21

|

|||

|

|||

|

I agree the foam will need to be coated with something it does not take long for it to start breaking down from UV. I sure wouldn,t want to take the chance with livestock involved if a couple bucks of coating would add a bunch of insurance.

I use the Great Stuff alot around my house and 1 day in the sun will make it yellow a great deal. After a week a powdery residue of eroding foam will come off if you rub on it. I know the Texas summer time sun has a bit more UV than tank lights but why take the chance. |

|

#22

|

|||

|

|||

|

I have been working on this idea for myself and have purchased some VERY strong magnets to in corporate into the back of the foam rock with another magnet on the on the back of the tank to hold it down. These magnets will put a blood blister on your fingers and are hard to get apart if they close with out something in between them.http://www.kjmagnetics.com/

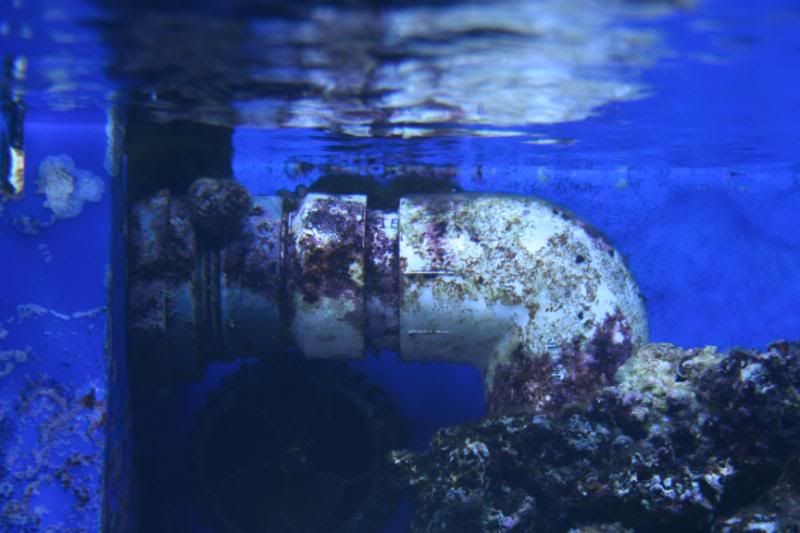

I explained to them that they would be used in saltwater and they recommended their epoxy coated magnets. I recently made some covers for my pump returns on an already running tank out of the pond foam and I am very happy with the results   notice cave with hidden vortech!! |

|

#23

|

|||

|

|||

|

Cool, magnets are a great idea!

__________________

Some people say, "How can you live without knowing?" I do not know what they mean. I always live without knowing. That is easy. How you get to know is what I want to know. - Richard Feynman |

|

#24

|

|||

|

|||

|

Quote:

Are you thinking that the sand coating that the guy in the thread did would not be enough to block the minimal UV from my metal halides. I'm guess I'm a bit skeptical since the foam I suggested using is designed for using in creating outdoor waterfalls in koi ponds and such. That plus the sand coating plus the minimal UV exposure is making me think that it's not going to be an issue. I know it's better to be safe than sorry. I will definitely let it "cure" for a while, before putting it in.

__________________

What if the hokey pokey is what it's all about? |

|

#25

|

|||

|

|||

|

Quote:

__________________

What if the hokey pokey is what it's all about? |

|

|