|

|

|

#76

|

|||

|

|||

|

The Red Dragons simply swap the ceramic shaft for the alloy one.

I would not be so sure. As was mentioned, the housings may be the same, but it is very trivial to wind the motors differently. They may have even added poles to ensure that the motor always starts in the same direction and has more torque. Most motor OEMS will happily wind to spec, the bobbins/armatures are wound by computer. It is trivial to change the number of turns or use a different pole piece. |

|

#77

|

|||

|

|||

|

Quote:

4", 5", and 6" diameters for $35, $80, and $120 respectively. I also checked nylon, teflon, and acrylic prices but PVC is the least expensive. A 1-foot rod should permit you to turn at least 3 volutes and perhaps 4. The only question now is how large diameter do you want to try? |

|

#78

|

|||

|

|||

|

i would think a 4" OD volute would give you enough room for a 2.5-3" meshwheel. i don't have my pump yet so i am not sure how big a volute would fit on them. i am not sure wether to get a 5000, or 7000 pump. looking to make a 12-18" diameter skimmer.

how do you all think thes pumps will hold up to head pressure? could you put this on a skimmer with a 36" reaction chamber? if so, what pump would be best for that size skimmer. i wnat to get in on this action...just don't want to buy and mod 2 different pumps if i don't have to.

__________________

Jeff |

|

#79

|

|||

|

|||

|

Quote:

take a look at these...holow rod they are cheaper...and we don't need that pesky middle anyway  or we could try this...you could see whats going on inside this way Clear pvc it's even cheaper!!!

__________________

Jeff Last edited by JCTewks; 04/14/2007 at 03:43 PM. |

|

#80

|

|||

|

|||

|

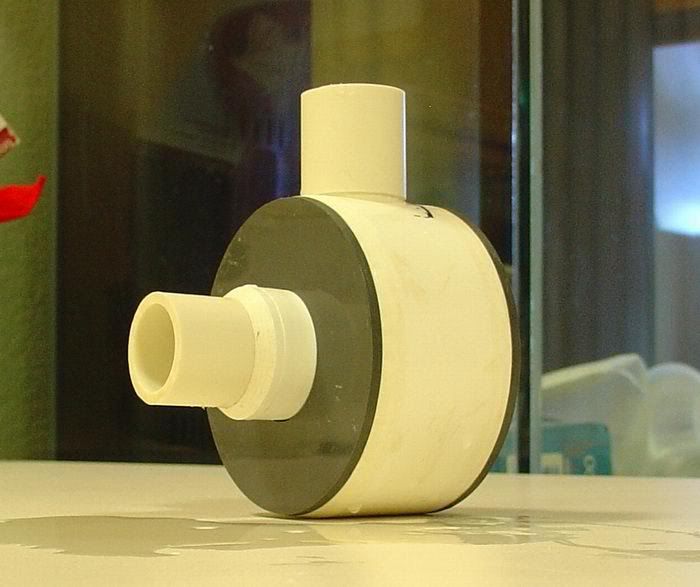

Some older pictures that show how I attached the impeller housing to the pump.

http://www.dfwmas.org/Forums/viewtopic.php?t=29391 |

|

#81

|

|||

|

|||

|

Quote:

I was testing the 901/110/5000 today, and its impeller started the same direction 90%+ of the time. Something tells me that in water, it most likely starts all the time in the same direction. When I used a 901 for a MJ-Stream mod, I never needed a stopper. As for the larger pumps, you can see that the impellers are the same as the RDs... and they are 'swirled' fins... indicating that they must spin the same direction every time. So the startup direction, at least with the 6-series on up, would be a non-issue. You could be right though... the windings might be different... no doubt to conserve energy. Something tells me that the two smaller series (901 and utility 5) most likely arent used by RE because they have that double ended shaft and may not start 100% of the time in the same direction... while the 6 series on up doesnt have the full shaft or the direction problem... and none of the RDs seem to have the double ended shaft. So Laguna might take the disk supported impeller and wind it in to a smaller pump/lower wattage pump. But in the end, what would it really add up to? I might end up with a Red Dragon meshwheel that uses 10% more electricity than the real deal or something... or will wear through the ceramic shaft every 2-3 years... Seriously, Im asking here... do you think it could actually mean that much? The direction of rotation seems to be controlled by the Lagunas as well... more torque though... why? A needlewheel would need less... except at startup maybe. If anything I could see less windings for less energy use. I wish quangtam7 had an air meter... his version may have just solved all our questions. quangtam7, if possible, I would like to see the inside of the volute you made. I am interested in how you dealt with the machine screws that hold the stock volute to the pump. I picked up the 3" PVC cleanout adapter which I believe is also what you are using, but the holes line up to be right under the material. That could be a small hurdle.

__________________

"If at first, the idea is not absurd, then there is no hope for it" -Al Einstein |

|

#82

|

|||

|

|||

|

Guys, lets step back here...

A centrifugal pumps wet end is an engineered chamber that is designed to work hand in hand with the torque curve of a given motor and a given engineered impeller. Yes folks, there is science behind how a pump works... pressure and veolicty and our friend Bernoulli. It is one thing to mess around trying to get finer bubbles, it is another thing trying to get more flow or a higher effective head. Just making a "bigger volute" is like saying "lets toss these wings on that airplane and see what it does". Just trying to keep things in perspective. |

|

#83

|

|||

|

|||

|

Quote:

Sorry, but did you read everything in the thread before you posted? I covered all these topics already.

__________________

"If at first, the idea is not absurd, then there is no hope for it" -Al Einstein |

|

#84

|

|||

|

|||

|

Less windings does not mean less energy use

You want the pump at BEP (best operating point) for the target output. In other words, you match the motor, impeller and housing to the desired output parameters. They can work at the problem from many angles, but motor windings are easy to adjsut. Better motors have more, finer windings. They operate cooler and with more torque. Better motors have heavier formers that do not saturate as easily. |

|

#85

|

|||

|

|||

|

Quote:

__________________

David - |

|

#86

|

|||

|

|||

Alright, above is the 3" cleanout adapter... its slightly larger than the 3" pipe, and it looks like what quangtam7 used on his. It has the right diameter, but when you see it from the inside, the screw ports are blocked. The little mounting nubs on the surface of the pump are cleared though and actually hold the the coupling right in place.  The 4" cleanout is made with a pipe size attachment instead, so its OD is just about 1/2" wider than the 3" cleanout. This one looks just too big on the pump though... and considering the real RD shrouds have a much thicker wall, I would imagine that this shroud would be too large. What might happen if the volute is too large of diameter? Well... volume of flow can go up... to a certain point... but you also start to lose pressure. The pump would be able to handle lots of air in its volute but not be able to get it anywhere very well. The 3" piece might be too much already. My concern is how to get around those two bottom machine screws then... I have to be able to get to them... or wait... do I... hmmm.... The holes for those two maching screws could be slotted, so that they could be screwed in, then slid down and then the other two can be screwed in...hmm...

__________________

"If at first, the idea is not absurd, then there is no hope for it" -Al Einstein |

|

#87

|

|||

|

|||

|

Bean: You're very close, you must first decide what sort of pump performance you desire. Use that information to compute the specific speed, a unit-less number. Using that you design the impeller, volute, and choose the appropriate driver (motor) which meets the performance characteristics spec'd in the beginning.

Pump design is that simple. On the other hand it is not a simplistic process. |

|

#88

|

|||

|

|||

|

Here was my idea for the new volute...

__________________

"If at first, the idea is not absurd, then there is no hope for it" -Al Einstein |

|

#89

|

|||

|

|||

|

Quote:

well use PVC pipe from HD/Lowes instead. With any hollow rod/pipe, a flat PVC piece must be glued on to create a closed vessel . I'd rather create a solid piece on the lathe. Quote:

sections. Much more expensive. |

|

#90

|

|||

|

|||

|

Quote:

Bean |

|

#91

|

|||

|

|||

|

Quote:

there was no engineering there. just mount the smallest wing surface possible to the largest engine posible and leave it up to the pilot to figure out. ok, i know thats a bit out there, still.... there was no engineering there. just mount the smallest wing surface possible to the largest engine posible and leave it up to the pilot to figure out. ok, i know thats a bit out there, still.... bean we had this argument about reflectors. sure some are highly engineered and some are not. so there is the possibility that all they did was take a motor and put a huge volute on it. another analogy would be grab that truck engine, bore it out and slap it in that firebird. not a whole lot of engineering needed but it makes that firebird the fastest in the hood. why a truck engine? (curious who knows). |

|

#92

|

|||

|

|||

|

Well, most AC pumps in this category should be 1800rpm... the pumps shouldnt slip that much, right? Its not like were talking variable speed Red Dragon 2s here that could be anything from 1000-5000rpm.

My approach is that yes, the pump can be designed around the desired output, but Im thinking we can have the output determined by the pump that we have. Once I get a working version, I can manipulate the threadwheel diameter and thickness to bring the power factor back up to normal operating range, and enlarge the wheel until the wattage gets up to near stock as well. Thats how I did the Aquaclear 802 mod... I watched the power factor and wattage... kept going larger until the wattage and power factor lined up as much as possible with the stock pump at 20 watts... I ended up at 18 scfh/500lph... right up there with a H&S/Deltec/DAS Aquabee 2000. Look at the ATI threadwheel... a 40 watt pump (think it really runs at 23 watts as is), a large volute and plumbing, and it gets 1000lph with a threadwheel. That pump was not approved for that use, nor was it designed for it... and yet it works better than the Sicce approved, designed, and engineered version for Tunze. By manipulating the thickness and diameter of the impeller/meshwheel/needlewheel, I can manipulate the speed of the pump as well. Im working in reverse, but who knows. I did ask Klaus today. He sent me a PM about some other stuff, so I figured Id ask him how 'custom' the RD pumps are. douggiestyle, why a truck engine? Well... thats what Dodge Vipers are. That V10, as well as most of the suspension and frame components on the original were dodge truck bin parts.

__________________

"If at first, the idea is not absurd, then there is no hope for it" -Al Einstein |

|

#93

|

|||

|

|||

|

Klaus actually responded to your questions? That would seem odd since this is meant to duplicate one of his pumps.

Nice thread, keep up the good work! |

|

#94

|

|||

|

|||

|

Man, that last drawing with the acrylic flange is exactly what I drew out on paper. I drew out the template to cut the flange earlier today. I am going o do it with the Laguna Power Jet 5000.

I love experimenting with this stuff! Mike |

|

#95

|

|||

|

|||

|

some pictures

Volute is ~3.5" id, can be reduced to 3" by inserting a short piece of 3" pvc pipe. Back 1/2" thick

|

|

#96

|

|||

|

|||

|

The truck v10 and the viper v10 are 2 different monsters. the truck is all cast iron parts and the viper is aluminum. the engine in the rt10 is a viper engine.

Anyway.............This is an awesome idea. I am following along I have a bunch of ac 5000's laying around. I LOVE DIY

__________________

Holy freaking cow I have a 1 year old!!!!! 11-25-06 |

|

#97

|

|||

|

|||

|

quangtam7, it looks like quite a bit of work went into that one.

What doesn't make sense to me is just how it attaches to the pump. I see in the 1st pic you have the 4 holes ... I assume that's how you bolt/screw it to the pump. Then in the 2nd pic I don't see any holes. I wouldn't imagine you made this to where it couldn't be removed ... I'm sure I'm just not seeing it. I can only figure that you made ‘like a flange’ and bolted it to the pump then glued the volute to that plate … but that would make it non-removable … well at least not without some effort. So you made it so that the inlet plate unscrews from the volute? |

|

#98

|

|||

|

|||

|

the truck version has thicker cylinder walls so you can bore it out more than the auto version. of course it would depend on the model year. i dont do this stuff, i just drink beer and watch my neighbor.

|

|

#99

|

|||

|

|||

|

Quote:

, here again http://www.dfwmas.org/Forums/viewtopic.php?t=29391 , here again http://www.dfwmas.org/Forums/viewtopic.php?t=29391

|

|

#100

|

|||

|

|||

|

Quote:

Makes a lot more sense now. |

|

|