|

|

|

#1

|

|||

|

|||

|

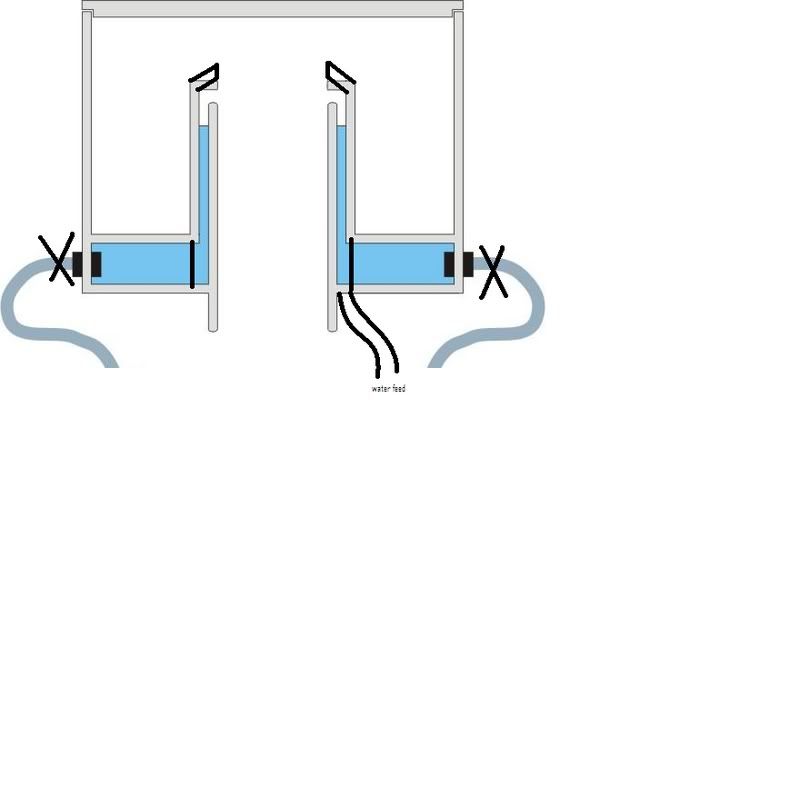

I am interested in building a skimmer with a gravity-feed, a wetneck and a ring feed (or "halo" per Hahnmeister). To prevent them from clogging, I need to filter particulate matter from the gravity feed.

(1) How do spray injection skimmers (Downdraft, Beckett, AquaC) solve the clogging problem? (2) What is the best way to filter the gravity feed? Thanks! Here is a wetneck:  Here is an ring feed on an ATB skimmer:

Last edited by pjf; 09/23/2007 at 03:12 PM. |

|

#2

|

|||

|

|||

|

PJF

not sure on your questions, but i think you can improve your wetneck design. For one, you don't need two inputs to it as it will be one compartment. Also, I would drill into the bottom of the cup because that side is flat. You could also avoid the compartment on the bottom by injecting water for the wetneck right by the riser tube and from the bottom so your larger diameter "outer wall" on the wetneck goes all the way to the bottom of the cup. This would simplify the build |

|

#3

|

|||

|

|||

|

what i'm talking about:

|

|

#4

|

|||

|

|||

|

and you could make the outer wall of the wetneck quite a bit larger without affecting performance much. THis would make it easier to build.

|

|

#5

|

|||

|

|||

|

Thanks, Pbrown3701!

I will incorporate your suggestions. (1) As for the beveled ring atop the neck, is that a common item? Why is the bevel needed? (2) Per Escobal, my 100g system only needs a skimmer flow rate of 75gph. If I can get a wetneck flow of almost 75-gph, then I would not need a second skimmer inlet. Is 75-gph possible through the wetneck with a neck size of 4" to 5" diameter? |

|

#6

|

|||

|

|||

|

Okay, I see. The top of the neck tilts down towards the collection cup to keep foam from drying out atop the neck.

I'll work on ways to dismantle the wetneck for cleaning. Thanks for the suggestions! Last edited by pjf; 09/25/2007 at 09:55 PM. |

|

#7

|

|||

|

|||

|

Actually, if you keep the 'L'-profile chamber, then you can just make the base of the cup into a flange... when you undo the flange, you could be taking apart the wetneck.

__________________

"If at first, the idea is not absurd, then there is no hope for it" -Al Einstein Last edited by hahnmeister; 09/26/2007 at 08:57 PM. |

|

#8

|

|||

|

|||

|

What is the benefit of a ring feed?

I don't have preview to see details on the various types of skimmers so I'm not familiar with all the options that could be considered in a DIY. I'm looking to build a 10" or 12" recirc. Also, is there an RC thread for DIY skimmers that could be considered as one of the best sources of information on the DIYs?

__________________

ScubaTC |

|

#9

|

|||

|

|||

|

A Ring or Halo feed reduces turbulence by spreading out the incoming water across multiple smaller holes, like a spraybar. The wetneck keeps the neck from building up skimmate deposits.

__________________

"If at first, the idea is not absurd, then there is no hope for it" -Al Einstein |

|

#10

|

|||

|

|||

|

Thanks hahnmeister!

Is there an RC thread for DIY skimmers that could be considered as a very good sources of information on the DIYs?

__________________

ScubaTC |

|

#11

|

|||

|

|||

|

Nah, there is no one organized central source for this... they are spread all over the DIY forum.

__________________

"If at first, the idea is not absurd, then there is no hope for it" -Al Einstein |

|

#12

|

|||

|

|||

|

Quote:

calculating the water "sheet" thickness (or water thickness over a weir) in this type of problem is complicated. I believe you have to use an iterative method. You'd be better off just trying it. My "gut" tells me that 75gph is too much for a wetneck, but it's hard to say. |

|

#13

|

|||

|

|||

|

Wetneck Flowrate

Pbrown3701,

I've very little training in hydraulics and fluid dynamics but here is why I think a wetneck can accomodate a gravity feed of 75 gph. Per the drain size calculator (http://www.reefcentral.com/calc/drain.php): Quote:

Here are some initial calculations of the wetneck opening size based on circumference x slot height: • A 4" diameter wetneck with a 1/50" slot height has a larger opening than a 1/2" diameter pipe. • A 4" diameter wetneck with a 1/25" slot height has a larger opening than a 3/4" diameter pipe. • A 5" diameter wetneck with a 1/33" slot height has a larger opening than a 3/4" diameter pipe. • A 5" diameter wetneck with a 1/20" slot height has the same opening size as a 1" diameter pipe. I prefer the smaller 4" diameter wetneck with a larger slot height to allow particulate material to pass. Let me know if you think these wetneck slot heights are appropriate as I have neither accounted for flow resistance through a narrow slot nor accounted for sheet thickness over a weir. The great thing about Hahnmeister's design is that the wetneck slot height can be determined by the thickness of the O-ring at the bottom (red in diagram). Hahn, What is the reason for the short but wide open cylinder above the wetneck rim? Last edited by pjf; 09/28/2007 at 12:04 AM. |

|

#14

|

|||

|

|||

|

All lids have this. The air flow gets directed down, taking the foam with... helps keep skimmate from coming out of the lid dy directing it down, etc...

__________________

"If at first, the idea is not absurd, then there is no hope for it" -Al Einstein |

|

#15

|

|||

|

|||

|

Re: Wetneck Flowrate

Quote:

One way would be to try it. Try sending the entire flow down the wetneck. If it doesn't work, you can always add the feed ring inside as planned originally. Just don't seal the top of the reaction chamber until you know it works. ALso, 5" is a large riser tube diameter. How much air are you planning to push? |

|

#16

|

|||

|

|||

|

Well, that design I posted above to have the wetneck open up for cleaning would also allow for varying thickness as well. With one slot for the o-rings, you can actually use different thicknesses of o-rings... a thin one or thick one would very the slot thickness... as well as just the screws themselves... screw them down harder, and the slot will be thinner...

__________________

"If at first, the idea is not absurd, then there is no hope for it" -Al Einstein |

|

#17

|

|||

|

|||

|

Re: Re: Wetneck Flowrate

Quote:

Per P.R. Escobal's "Sizing Chart for Counter-Current Skimmers," a skimmer diameter of 4" to 5" should be appropriate for my 100 gallon system (http://www.hawkfish.org/snailman/skimmer101.htm). Escobal also recommends a 75 gph inlet flow for a 100 gallon system. For simplicity, I hope that the wetneck can handle all of the inlet flow and that the diameters of the riser and body can be the same. Here are two preliminary designs: (1) High Bubble Chamber (variant of Hahnmeister's Bubble Sphere)  (2) Low Bubble Chamber (Hahnmeister Design)  I plan to force-feed a recirculating needlewheel pump with an Alita AL-6A linear air pump. I want the air pump to inject at least 10 lpm (600 lph) of air into a skimmer through the recirculating pump. I believe the 5" skimmer can accept 700 lph of air (per Hahnmeister) and the 4" skimmer can accept 450 lph of air (extrapolation).  The recirculating pump will likely be the "External Skimmer Pump for DAS EX Skimmers" (http://stores.petorama.net/Detail.bok?no=51). I believe that it is the Aquabee 2000/1. I hope the fittings aren't glued to the pump as the union fittings are too far apart and are not configured for the low chamber design. The Eheim 1255 (http://www.charterhouse-aquatics.co....hr-p-1058.html) looks good for a small skimmer but I'm not sure when it will be available in the US. |

|

#18

|

|||

|

|||

|

Well, i'll be interested to see how it turns out. Be sure to document your progress

|

|

#19

|

|||

|

|||

|

THe only issue i see with Hans drawing above is that the riser tube is not removable (easily) for cleaning. OTher than that, it looks to have a lot of advantages.

|

|

#20

|

|||

|

|||

|

I'm not sure how a collection cup should mate with the skimmer body. In the design above, the riser and the skimmer body have the same diameter and are joined by a collar which is glued to the skimmer body. The riser can be lifted up and away.

|

|

#21

|

|||

|

|||

|

Yeah - so you could use that design with Han's wetneck design so both could be removed and cleaned.

If you can find a 5" True Union, that will be an easy "collar." You can cut down the slip fittings on the union so they don't cover much of the reaction body. Are you goign to use arcylic or clear PVC? Or just go with normal PVC (what i would do). You really only need the top of the riser to be clear so you can see the level. You could even use clear PVC |

|

#22

|

|||

|

|||

|

To reduce turbulence, I prefer that the internal joint between the riser and the reaction body be as smooth as possible. I'm not sure how to do that except with a slip collar joint.

To check out the air flow, foam formation, and turbulence, I'm going to have to use a clear material. My main concern is turbulence from the recirculation pump. I'm not familiar with clear PVC but will experiment with it if it is less expensive than acrylic. |

|

#23

|

|||

|

|||

|

Clear PVC is not less expensive (a little more actually). However, you can buy it in 1ft sections which is harder to find in acrylic. Also, you can use normal PVC fittings and glue - which is nice.

How tall are you going to make it? If it's more than 30" or so, turbulance in the top shoudn't be an issue. I don't think the Union would cause much turbulance either. If you use a slip coupling, do you plan to glue it together? If so, how will you get the neck off for cleaning? |

|

#24

|

|||

|

|||

|

what skimmer with wetneck already on them?

|

|

#25

|

|||

|

|||

|

Quote:

|

|

|