|

|

|

#26

|

|||

|

|||

|

it took me a little longer than expected to get this done, letting krylon fusion and silicone cure in freezing weather takes a lot longer than normal..

This thing works GREAT, it's one of those DIY's that everyone should be doing

|

|

#27

|

|||

|

|||

|

very cool. glad it worked out for you.

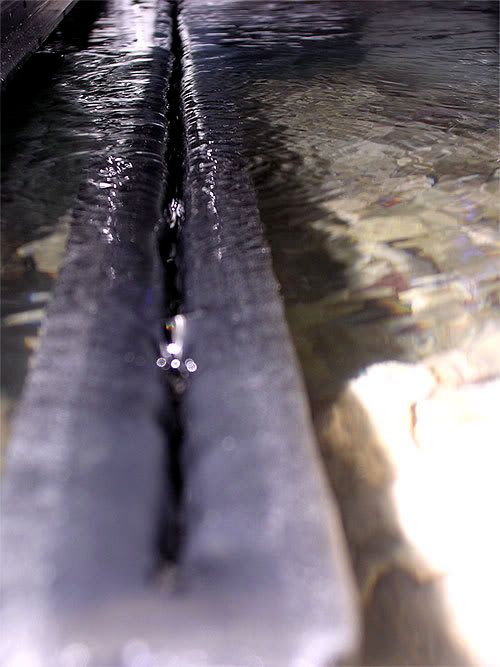

I noticed you didnt do the back up bulkhead and ball valve thing. what size pipe did you use and how is the noise?? How much flow are you putting through ti?? looks like 1.25......but hard to tell. just curious. ps- thats a sweet shot of the surface skimming action. I like it |

|

#28

|

|||

|

|||

|

thanks it was your original thread that actually gave me the idea to do it so I was glad when you posted in this thread because I lost yours.

The noise is not bad at all, can barely hear it - I have only 200 gph going through and it's 1" pipe. To be honest though the cube I have right next to it has a noisier overflow so I can't tell you if it would be bad in an otherwise quiet room. |

|

#29

|

|||

|

|||

|

Man - that looks great! I don't know why this concept hasn't made it MUCH bigger!

__________________

Dogs - Man's best friend; entropy's greatest catalyst. |

|

#30

|

|||

|

|||

|

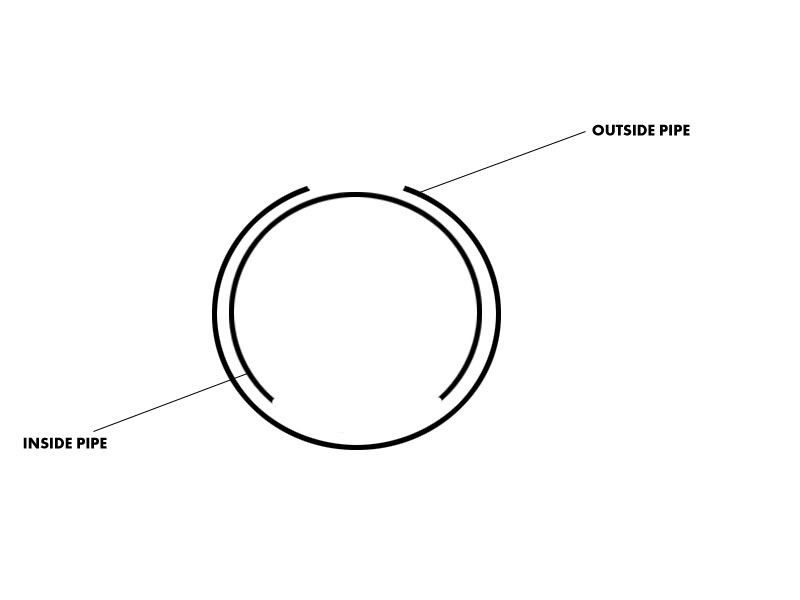

Im almost convinced that you could use a "double pipe" system that would have a slit cut in the top of the outside pipe, and a slit cut on the bottom of the inside pipe, basically creating a linear durso. This (IMO) would completely eliminate any noise that may arise from using this type of overflow system.

Does this make sense?

__________________

"You can't depend on your eyes when your imagination is out of focus." - Mark Twain |

|

#31

|

|||

|

|||

|

Quote:

You'd need to run the smaller pipe like in the original poster's pic, but with the slit down and using a tee instead of a 90 where the horizontal joins the drain (to allow placement of the standpipes inside the tank). A little creative hacksawing on a pair of big-to-little reducers to seal the ends of the big pipe. There is no submerged inlet to the drains in the Uhurus design, so no sound-muting durso. MeuserReef's soulution creates a submerged inlet/durso. Of course, if it's quiet already, perhaps this is just being too clever by half. I suspect, though, that it would allow for relatively less noise at greater flow rates. Plus, it's a very clever idea! |

|

#32

|

|||

|

|||

|

Looks like a great idea! But how would you keep the inside pipe from laying on the bottom of the outside pipe? I guess the end could have an adapter on it that would also fit inside the bigger pipe which would keep it elevated.

I'm not trying to tear your idea apart, I'm really curious about it.

|

|

#33

|

|||

|

|||

|

Quote:

|

|

#34

|

|||

|

|||

|

Quote:

Correct. If you look at uhuru's pic at the top of this page (pg 2). you can see that he's using 1" PVC 90 degree elbows to hold the horizontal pipe in place. If you were to get a larger diameter piece of pipe (say 2" maybe) that would go around / over the 90 degree elbow, you would then have your double pipe in place. There would still need to be an air escape on the inside pipe somewhere to allow the air inside of the pipe to be displaced with water. You make a good point that this would only be needed if the existing design was too loud. If measured properly, this could probably be a retrofit job for someone with the single pipe system inplace, allowing for a "mod" to make it quieter.

__________________

"You can't depend on your eyes when your imagination is out of focus." - Mark Twain |

|

#35

|

|||

|

|||

|

Ok, thanks. I see how that would work now.

|

|

#36

|

|||

|

|||

|

how would i use this type of overflow system if i didnt want to drill holes in my tank?

how deep would the pipe need to be to achieve a rate of 1300-1500gph? This is an awesome idea i just dont want to risk breaking my 150g tank by drilling holes into the glass so how would i work it out without using drilled holes? |

|

#37

|

|||

|

|||

|

Has anyone tried drilling a hole and inserting a vertical tube into the elbows inside the tank?

|

|

#38

|

|||

|

|||

|

I dont think this design would work without holes in the glass.

Drilling a tank is not as hard as it may sound.

__________________

"You can't depend on your eyes when your imagination is out of focus." - Mark Twain |

|

#39

|

|||

|

|||

|

Here's another crazy idea. Instead of cutting one long groove lengthwise.....maybe cut a couple dozen smaller grooves perpendicular?

|

|

#40

|

|||

|

|||

|

Quote:

Also, you do know this is an overflow design for a drain to the sump then back to the return, and not a closed loop? A 1300gph return is quite excessive. Making any drain able to handle that much flow is a challenge. Pretty much the full diameter of 2" pipe would be required everywhere. |

|

#41

|

|||

|

|||

|

Quote:

You could actually use just half a pipe for the internal one. The whole point is to reduce drop, right? And at the same time not restrict flow. |

|

#42

|

|||

|

|||

|

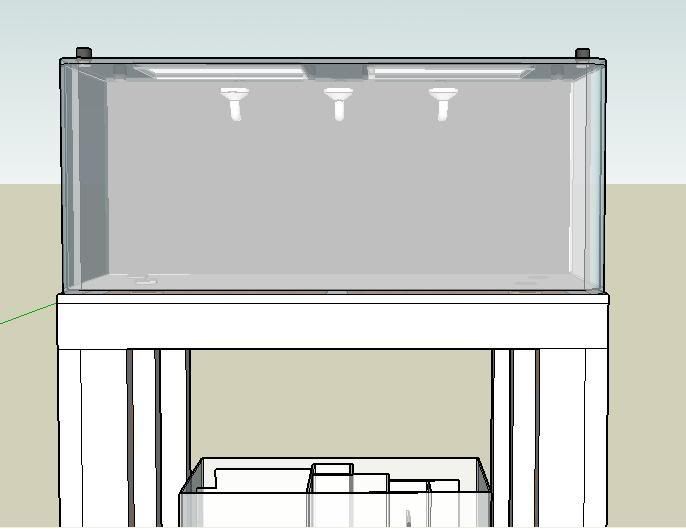

Alright, I had been looking for the thread on this type of overflow. Now I have my plans together. I will be drilling a hole at ech end of the tank and will actually have two of these running back to front on each end of the tank. I want to keep them as much out of sight as possible and since my DIY stand will cover the sides of the tank and only allow viewing from the front window, they should be hidden for the most part, especially after the coraline covers them. I also plan on using t's instead of elbows and that will allow me to cap them with a hole drilled in the top for air to escape. Of course since it will only be supported by the bulkhead on one end, I will have to drill a hole in the plastic frame of the tank and put a tywrap in to support the other end. Or since I have access to all the glass I need, I can make a small glass "U" and silicone it in to support the pipe once I have it in place. Then oly glue up to the "T", leaving the actual overflow piece press fit. Even if it leaks, it can't leak far and a little teflon tape works wonders even on press fit.

|

|

#43

|

|||

|

|||

|

Great idea and I like to keep this thread alive.........I wonder if using tow 45 degree elbows would make this quiter than having the 90's. The double sleeve idea sounds great. I plan on trying this using 1.5"pipe for the outer pipe and 1" pipe for the inside pipe. On each end of the 1 " pipe, there will be 1.5 " to 1 " adapter/ reducer fitting. The adpaters/ reducers will be sanded down on the inside to allow the 1 " pipe to slide all the way thru. The 1" pipe can then be connected to the elbows and bulkheads. For getting rid of the air, would putting y-tees on the outside have the same result as using t's on the inside of the tank? How can the herbie method be incorporated in this?

|

|

#44

|

|||

|

|||

|

Quote:

Im interested to see someone follow through with the sleeve idea. Do it and post results please

|

|

#45

|

|||

|

|||

|

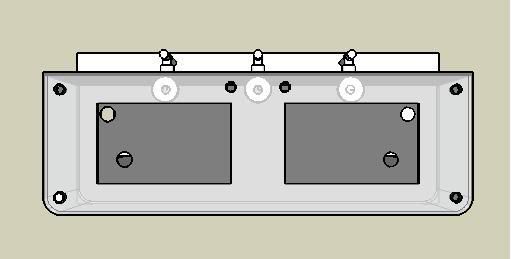

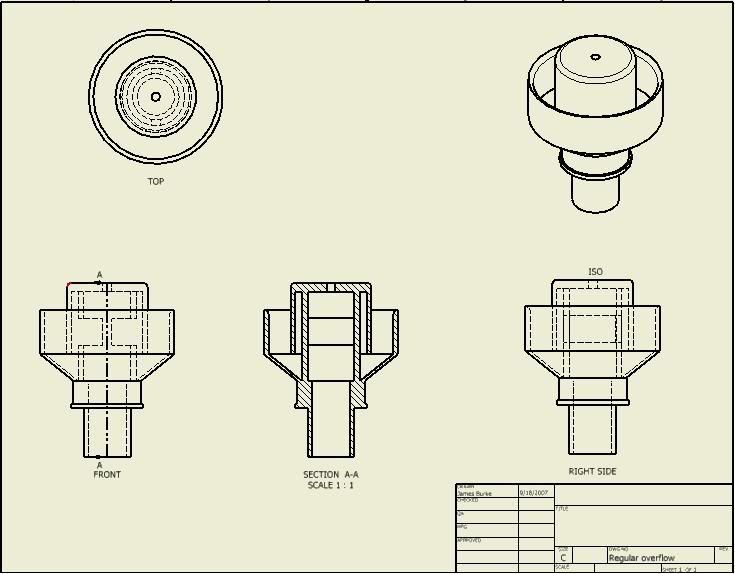

I have 2 holes drilled in my tank, and pvc overflows running right now. But instead of them being horizontal, I have them running vertical then adapted upward to 3 inch pipe, so I have about 19 (2x3pi), inches of overflow. Here are some pictures.

Front view (with 3 overflows) Slightly undersized  Top View  I also drew up a way to silence them.. This is untested so I can't vouche for it being silent. But it seems like it should be since the piece on top is like a modified stockman. I will get around to testing this one day  Right now they have an external durso on them. I can get some pictures of the real setup if anyone is intersted. |

|

#46

|

|||

|

|||

|

I used horizontal slit PVC overflows about 6 years ago on my first tanks that were drilled.

For some reason, they seemed to have an abnormally strong ability to rapidly grow turf algae in that slit. I finally resulted to making a black acrylic strip to shade the area, and it worked much better. I currently use horizontal layed vertical slit 4" pipe cut in half and siliconed to the back of the tank for my closed loop returns. It works very well. If you look on the back wall of the tank in this picture you can see what I'm talking about.  Here is a shot of when I first set the tank up.  It's been my only overflow design that has never sucked something into it other than water. It also has 2 2" pipes and bulkheads leading out of the tank. The overflows also use a pair of 2" bulkheads and seperate feeds to the sump. Redundancy is very important in returns. Just wait until you have a monster 16" RTBA decide to release an go free floating in your tank until he slides down your overflow and clogs your single 2" bulkhead solid, and you pump 150 gallons of saltwater onto the floor... A friends tank did a similar thing with a wadded up plastic fish bag that was floating in the tank. Managed to block off enough of his single large durso that he pumped all the water in is sump onto the carpet... Redundant overflows are always a good idea. |

|

#47

|

|||

|

|||

|

uhuru did you paint your pvc? what paint is safe to use?

|

|

#48

|

|||

|

|||

|

I used krylon fusion, it's safe to use

|

|

#49

|

|||

|

|||

|

You could use one of those fittings that allow hoses of different sizes to attach both pipes together. I don't know the name of it but here's a pic of one. The one in the middle of the left side. As for getting rid of the air inside, just install the overflow, fill the tank with water and rotate it until all the air is removed. Problem solved.

Btw liveforphysics, I like your design as well. No surface skimming though. |

|

#50

|

|||

|

|||

|

Quote:

|

|

|